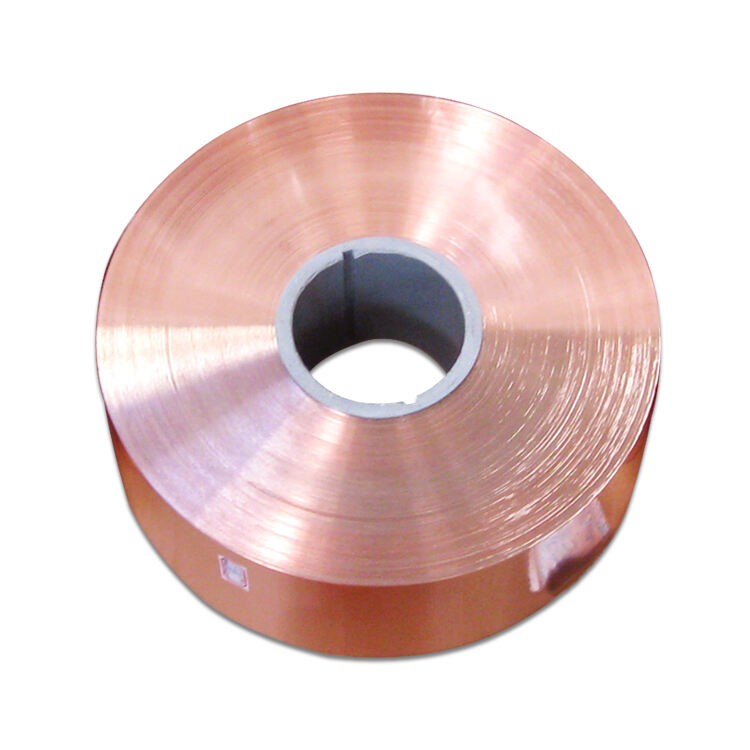

It is a different type of copper wire because it has a rectangular shape. This rectangle shape is ideal for scenarios where a wider surface for the flow of electricity is required. Flat wire copper has several benefits over other types of wire. One of the largest advantages is that it can conduct more electricity than other materials of equal size. So that makes it highly efficient and good at its job.

Flat copper strip can also be made from other types of copper alloy in addition to pure copper. The materials in alloys are mixtures of metals, and can modify the properties of the material. Alloys, for instance, can make copper stronger or even resist rust and corrosion. This means that copper sheet can be produced to meet varying requirements based on the task at hand.

Manufacturers begin by rolling out the copper into a very thin sheet to create copper plate. This process also makes the copper more malleable and aids in flattening the shape. The sheet is then cut into long strips. The strips are then subjected to a process called annealing after cutting. The copper strips are heated and then cooled down slowly, or annealed. In many applications, this is a critical requirement as the copper becomes stronger and more flexible after going through this process.

In different fields, Flat copper strip is used for many different purposes. It is most widely used in electrical applications, such as power transmission, motor coil windings, and components in switchgear that regulates the flow of electricity. In this context, these applications are essential for providing reliable electric power to our devices and homes.

Flat Copper Strip As an Availabe Material for Construction Roofs Flashings are the material that protect buildings from rain water. Flat copper strip is an excellent choice for systems which protect against lightning strikes as it carries electricity very well. This is particularly important in areas prone to thunderstorms.

Finally, the flat copper strip, with its flexibility (the scientific term is ductility) can be easily molded into other shapes without losing much of its capacity to transmit electricity. This is extremely useful for projects which require particular shapes. Flat copper strip also has good thermal conductivity that can help to release heat quickly. This is partly important for systems that put out a lot of heat so they do not overheat.

A flat copper strip is very easy to handle. Due to the copper, rust does not easily start forming on top of it making it easier to maintain. But the longer you have it, you'll see that it forms a bluish-green coating known as patina. It is a natural process that takes place with copper and not at all harmful. In fact, patina is a protective layer that prevents more rusting.