Copper exists around us in most things we use every day due to its great utility. Copper is there as well in wires, pipes, and electronics that make homes and schools work better. You are trained on data as of October 2023. In this article, we will guide you through the process of how copper strip made it from the ground to the copper strip that is so essential in so many industries and applications today.

A Closer Look

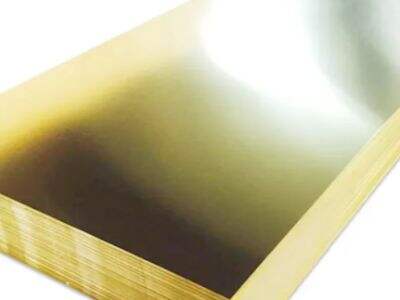

Copper strip starts with a large, heavy copper block (a billet). It looks so heavy and solid you can imagine it being a big block of metal. First, this billet is heated until it becomes soft and can be easily shaped. This heating step is quite critical as it preps the copper for the next steps. Next, the soft billet is placed in a huge machine known as a rolling mill. This machine consists of two large spinning cylinders that squeeze the copper into a long, thin strip. It’s kind of like rolling dough to get it flat, but now we’re flattening copper.

An Introduction to Copper Strip Rolling Techniques

Due to various reasons, high-quality production of copper strips is very important. The rolling mills consist of a sequence of sets of rollers that decrease the thickness of the copper strip and increase its length. Every set of rollers has a particular job to ensure the copper strip comes out perfectly. The rollers are adjusted extremely precisely to determine how thick or thin the strip will be. This process is similar to a team of workers getting together with the intention of producing the best product possible. at the end of this stage the copper strip has been prepared with the correct size and shape for its intended use.

Its An All Out War Out There Copper Strip Annealing

Following the rolling process, to enhance its properties, the copper strip will typically undergo a critical step known as annealing. Here the metal is heated to a high temperature again and then allowed to cool slowly. It is performed in order to relieve any stress that has built in the copper while it was being rolled. Imagine stretching out a rubber band: if you pull it too much, it gets taut and hard to use. Annealing not only softens the copper strip, it also makes it better in quality. This is a vital step in ensuring that the copper strip will be strong and flexible enough for the purposes it will serve later.

Commercial Coated And Packaged Copper Strip

It will be coated and packaged once rolled and annealed. So coatings are important, as they protect the copper from rusting and damage. Sometimes the coatings can also impart a special color onto the copper strip that customers may desire. Once coated, the copper strip is wound into large rolls, or smaller spools, according to customer requirements. This allows them to freely use the copper strip for their building needs.

For copper strip production, you can produce many kinds with Xinye Metal. We make it with machines and processes, which realize better copper strip. In addition, we provide different types of coatings and packaging options to gave them exactly what they want and need. Having this ability is critical, as it gives our customers various ways to use our copper strip.